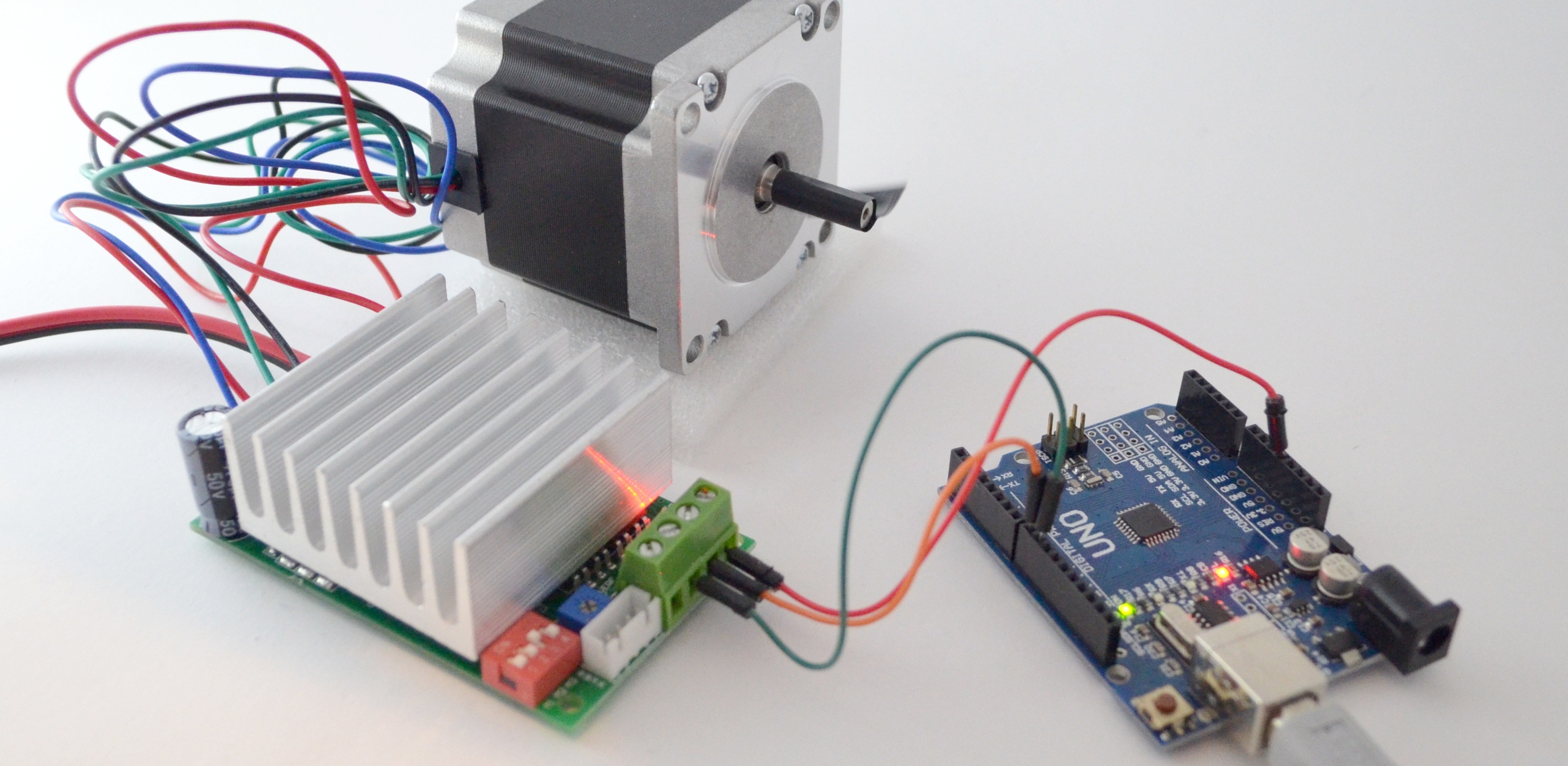

It can become a drop-in replacement for the motors on a normal CNC or 3D printer, which have full closed loop control as shown in the video after the break. The board supports lots of standard communication protocols, but the acceptance of regular stepper inputs make it extra interesting. Opening up the control allows for interesting applications, such as motors that behave like mass spring damper systems, or electronically gearing the input of one stepper to the output of another. Most industrial controllers are limited to PID control, for returning to the last sent position. On top of this, it also allows the user to use any control algorithm they want for the board.

They wanted the board to be as accessible as possible. The brains of the board is the compatible, SAMD21 ARM M0+ chip. He Arduino-sounding bit of the name comes from their full compatibility with the Arduino development environment. That’s exactly what the Mechaduino does. They also hint at doing something very clever with a magnetic encoder on the board which allows them, after a calibration routine, to get the accuracy they’ve promised. Whenever we post something about using cheap brushless motors for precision control, someone comments that a stepper is just a brushless motor with a lot of poles, why not just control it like one. Is it something in the water, or have there been a lot of really cool servo projects lately? Mechaduino is a board that sits on a regular stepper motor and turns it into a servo with a closed loop control of 0.1degree.

0 kommentar(er)

0 kommentar(er)